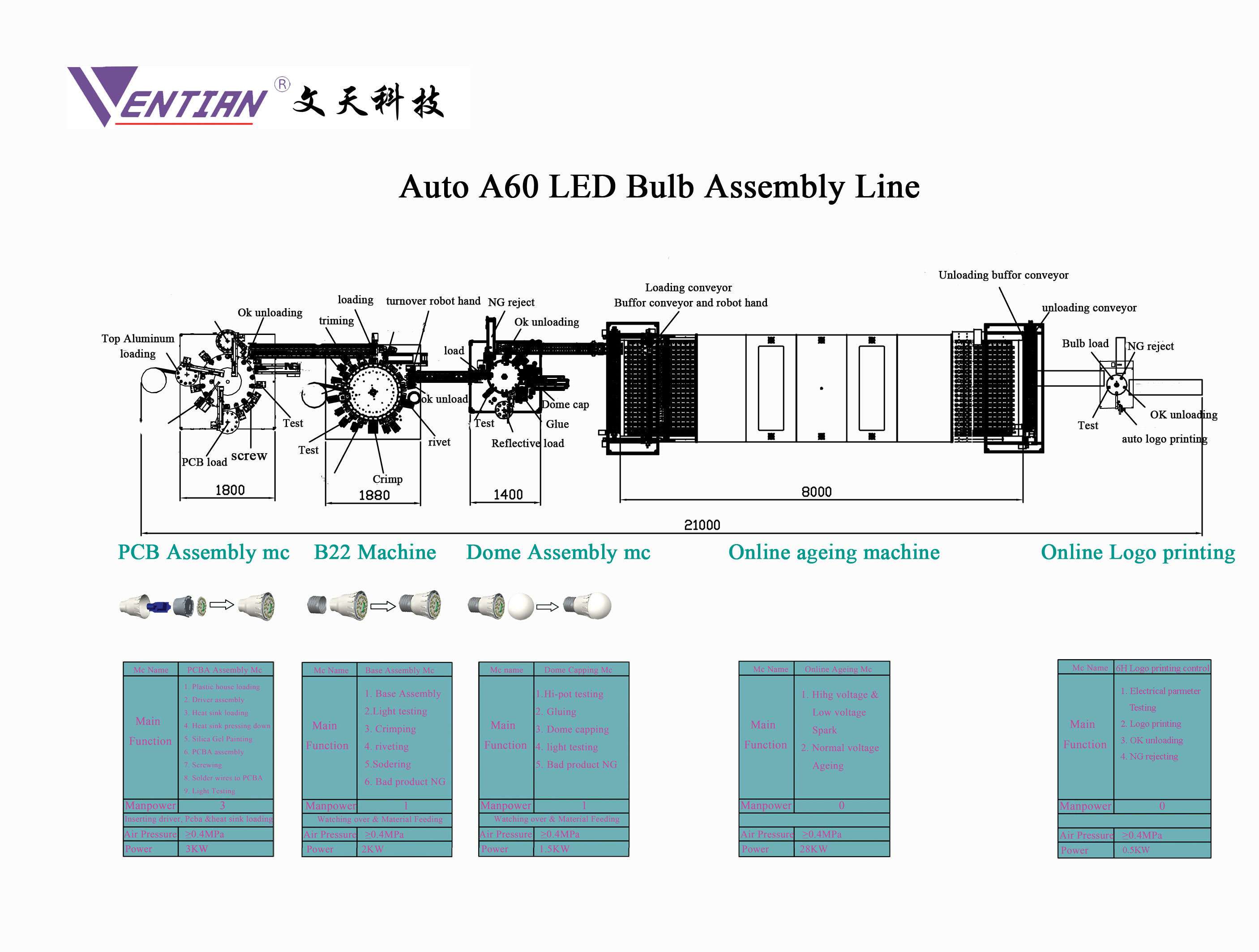

Cleaning and logo printing Contral Stage

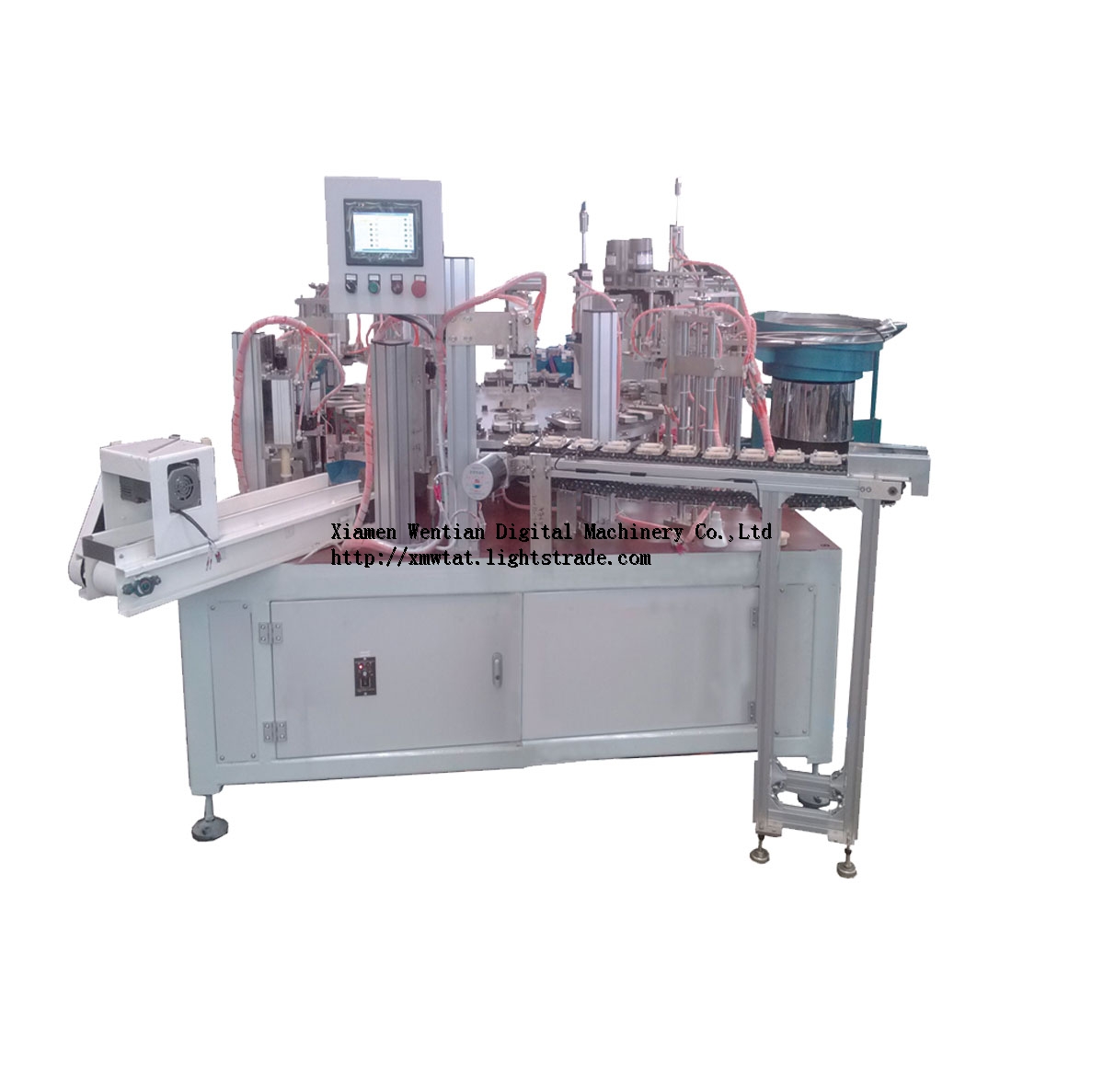

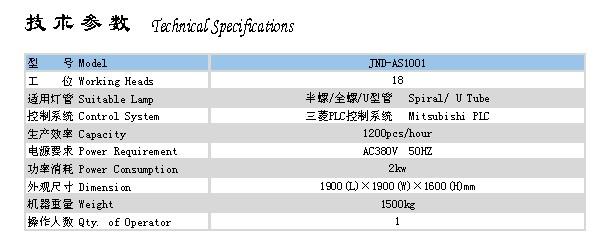

AUTO CFL Assembly Machine

MOQ :1 piece

Lead Time :15 Days

Seller Support : Trade Authenticity Guaranteed & Accepting

Payment : L/C,T/T

Departure Port : Xiamen

Product details

Supply Ability

- Supply Ability:5 piecesWarranty(Year):1 Year

Packaging & Delivery

- Length:10000 cmWidth:2000 cm

- Height:1500 cm

- Packaging:1 piece

Product Specifications

Product Description

产 品 优 势 Advantages

- Several operating procedures are integrated in one machine, improving the working efficiency.

Capacity is 6 times than the traditional working way. - Less manpower needed, less labor cost.

- High space utilization.

机 器 性 能 Introduction

1、节能灯整灯自动组装机可将套好上盖的节能灯组合件、灯头、铆钉等零部件自动组装成完整的节能灯,并通过检测将不合格的节能灯分开,输出完整、合格的节能灯。

The automatic assembly machine can combine glass tube, plastic cap, base and rivet automatically, then test and sort out the unqualified lamp output the finished and qualified lamp.

2、机器主体采用18工位圆周间歇分割运动机构,并配变频器调速。

The main body of machine which adopts 18 heads circumferential indexing drives is equiped a frequency converter to adjust speed.

3、手工将套好上盖的节能灯组合件放于上灯转盘,自动完成压上盖、上灯管、校正、理灯线、剪灯线、上灯头、旋灯头、通电检测、打钉、压灯线,上铆钉,压铆钉、下管。

Place the semi-finished lamp on the loading plate, the machine will automatic assemble following the sequence below :

Capping – Loading – Revising - Lead wire trimming – Lead wire cutting – Base loading and screwing – Connecting test – Riveting – Unloading.

4、自动检测,采用工业显示器显示灯的工作及电流情况;自动停止不合格品的后续加工步骤,并筛选流转出来。

Automatic testing, the working status and parameter of current will be displayed on the screen. Automatic stop the rest processes of unqualified lamp, and sort them out.

5、可实现自动连线操作。

Capable of connecting to automatic production line.

You May Like

- Exhibitor

- Gold Supplier

- Trade Assurance

Business Type : Manufacturer,Service,Exporter

Company Location: FU JIAN

Year Established: 19YRS